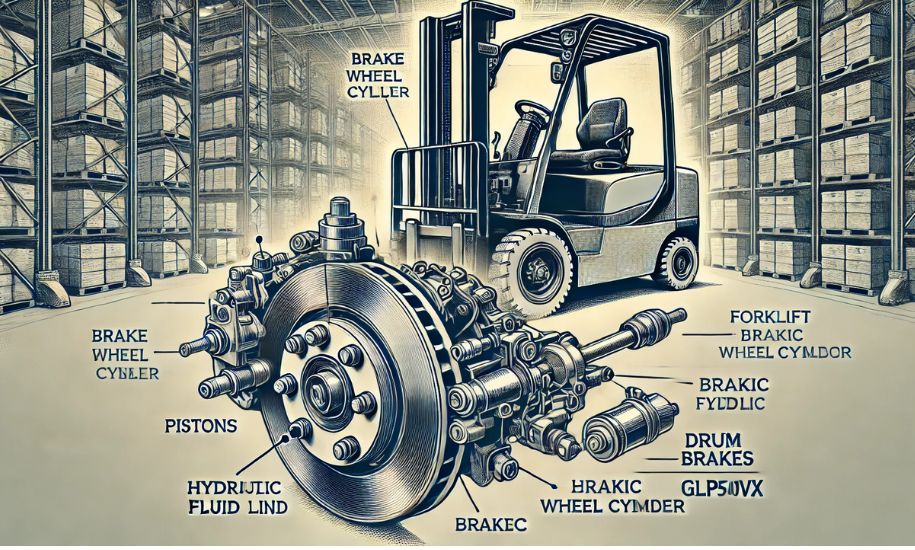

When it comes to the braking system of heavy-duty forklifts, one crucial component that ensures safe operation is the brake wheel cylinder. For those who own or operate a Yale GLP050VX forklift, understanding how the Glp050vx Brake Wheel Cylinders work, their importance, and their maintenance is essential. This article will provide an in-depth look at these critical braking components, their functionality, and why regular maintenance is crucial for safety and efficiency.

What is a Brake Wheel Cylinder?

A brake wheel cylinder is a hydraulic component that plays a key role in the braking system of forklifts, trucks, and other heavy machinery. It is responsible for converting hydraulic pressure into mechanical force, which in turn pushes the brake shoes against the drum to slow down or stop the vehicle.

In the case of the Yale GLP050VX, the brake wheel cylinder is a vital component that ensures smooth and effective braking. When the operator applies the brake pedal, hydraulic fluid moves into the cylinder, pushing pistons outward and pressing the brake shoes against the drum to create friction, which slows down the forklift.

Key Features of Glp050vx Brake Wheel Cylinders

The Glp050vx Brake Wheel Cylinders are designed to meet the demands of industrial forklifts. Here are some of their key features:

- Hydraulic Efficiency: These cylinders efficiently transfer hydraulic pressure to apply braking force.

- Durable Construction: Made from high-quality materials, they withstand heavy-duty operations.

- Smooth Operation: They ensure even and controlled braking, reducing wear and tear.

- Corrosion Resistance: Many of these components are coated to resist rust and corrosion, increasing their lifespan.

- Compatibility: They are designed specifically for the Yale GLP050VX model, ensuring a perfect fit and reliable performance.

Importance of Brake Wheel Cylinders in the Yale GLP050VX

Without properly functioning brake wheel cylinders, a forklift’s braking system can fail, leading to accidents, injuries, or damage to goods and property. Below are the main reasons why these components are crucial:

- Safety: A forklift with failing brake cylinders can become a major hazard in warehouses and industrial settings.

- Efficiency: Properly functioning brake wheel cylinders ensure smooth braking, preventing abrupt stops that can disrupt workflow.

- Reduced Wear and Tear: Faulty cylinders can lead to uneven braking, causing premature wear of brake shoes and drums.

- Cost Savings: Regular maintenance and timely replacement prevent expensive repairs and downtime.

Common Issues with Glp050vx Brake Wheel Cylinders

Like any mechanical component, Glp050vx Brake Wheel Cylinders can develop issues over time. Some common problems include:

- Brake Fluid Leaks: If the seals inside the cylinder wear out, brake fluid can leak, reducing hydraulic pressure and causing braking issues.

- Corrosion and Rust: Exposure to moisture and chemicals can lead to corrosion, affecting performance.

- Sticking Pistons: Dirt or wear can cause the pistons to stick, leading to uneven braking.

- Loss of Hydraulic Pressure: If the cylinder fails, the braking system may not generate enough pressure to stop the forklift effectively.

How to Maintain and Replace Glp050vx Brake Wheel Cylinders

Proper maintenance can extend the life of brake wheel cylinders and ensure the safety of the forklift. Here’s how you can maintain and replace them:

Maintenance Tips

- Regular Inspection: Check the brake system for leaks, cracks, or signs of wear.

- Fluid Check: Ensure that the hydraulic fluid is at the proper level and is not contaminated.

- Clean the Components: Regularly clean the brake components to prevent dirt and debris from causing malfunctions.

- Replace Seals When Needed: If you notice leaking fluid, replacing the seals can help extend the life of the cylinder.

Replacement Guide

- Gather Tools: You’ll need wrenches, a brake bleeder kit, and replacement parts.

- Lift the Forklift: Securely raise the forklift to access the wheel cylinders.

- Remove the Brake Drum: Detach the drum to reach the wheel cylinder.

- Disconnect the Cylinder: Remove the hydraulic lines and bolts holding the cylinder in place.

- Install the New Cylinder: Secure the new brake wheel cylinder and reconnect the hydraulic lines.

- Bleed the Brakes: Remove any air from the brake lines to restore full braking efficiency.

- Test the Brakes: Before putting the forklift back into operation, test the brakes to ensure they work properly.

Where to Buy Glp050vx Brake Wheel Cylinders

If you’re looking for replacement brake wheel cylinders for the Yale GLP050VX, several suppliers offer high-quality parts:

- ES Forklifts: Specializes in Yale forklift parts, including brake components.

- All Forklift Parts: Offers a wide range of OEM and aftermarket brake wheel cylinders.

- Helmar Parts: Known for their durable and high-performance forklift components.

Conclusion: Glp050vx Brake Wheel Cylinders

Understanding the role of Glp050vx Brake Wheel Cylinders is crucial for maintaining the safety and efficiency of your Yale GLP050VX forklift. These hydraulic components ensure proper braking function, preventing accidents and unnecessary repairs. By performing regular inspections, timely maintenance, and replacing faulty cylinders, you can keep your forklift in optimal working condition.

For more in-depth guides, reviews, and industry insights, visit our blog, Empire Magazines, where we provide detailed information on forklift maintenance and components.